Introduction to Smart Packaging Machinery

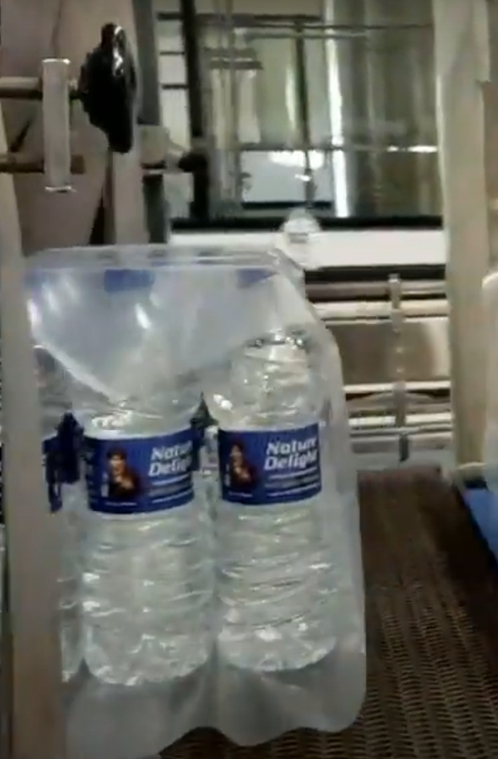

Smart packaging machinery is revolutionizing the way businesses operate. Gone are the days of traditional packing processes that were often time-consuming and wasteful. Today, companies are turning to innovative solutions designed to streamline operations while minimizing environmental impact. Picture a world where efficiency meets sustainability – that’s the promise of smart packaging technology.

Imagine machines that not only speed up production but also optimize material use, leading to less waste and higher profitability. As industries evolve, so does their approach to packaging. Smart machinery integrates advanced technologies such as sensors, automation, and artificial intelligence, delivering benefits you may never have thought possible.

In this blog post, we’ll explore how smart packaging machinery increases efficiency and reduces waste in various sectors. From case studies showcasing real-world applications to insights on future trends shaping the industry—this is your guide to understanding why investing in smart packaging could be a game changer for your business.

The Advantages of Implementing Smart Packaging Machinery

Smart packaging machinery offers a plethora of advantages that can transform production lines. First and foremost, these technologies enhance accuracy. With precise measurements and automated processes, businesses can minimize errors that often lead to product wastage.

Speed is another significant benefit. Smart systems operate at impressive rates, allowing companies to boost output without sacrificing quality. This efficiency translates directly into higher profit margins.

Moreover, adaptability plays a vital role in today’s fast-paced market. Smart packaging machines can be easily reconfigured for different products or package sizes, reducing downtime during transitions.

Cost savings are also noteworthy. By optimizing material usage and energy consumption, these machines help lower operational costs over time.

The integration of real-time data analytics empowers businesses to make informed decisions swiftly. This ability not only improves operational performance but also fosters sustainability efforts by highlighting areas where waste reduction is achievable.

Case Studies of Companies Using Smart Packaging Machinery

Several companies have embraced smart packaging machinery, showcasing remarkable benefits. A notable example is Coca-Cola, which integrated advanced technology into its bottling process. This shift not only streamlined production but also enhanced quality control.

Similarly, Unilever has implemented smart packaging solutions in their supply chain. By utilizing real-time data analytics, they reduced downtime and improved inventory management.

Another impressive case is Nestlé’s use of automated packing lines. These machines adapt to different products seamlessly, minimizing changeover times and maximizing output.

Smaller firms are also seeing gains from this technology. Local food producers that adopted smart packaging reported a significant reduction in labor costs while increasing efficiency.

These examples illustrate the diverse applications of intelligent machinery across industries. Each success story highlights how these innovative systems can transform operations and drive growth.

How Smart Packaging Machinery Can Reduce Waste

Smart packaging machinery plays a pivotal role in waste reduction across various industries. By optimizing the packaging process, these advanced systems minimize material use while ensuring product integrity.

Through precise measurements and automated adjustments, they significantly cut down on excess materials that often end up as waste. This is especially vital for businesses aiming to uphold sustainability standards.

Furthermore, smart machinery can adapt to different products seamlessly. This flexibility reduces the need for multiple types of packaging, leading to less scrap and more efficient resource utilization.

Data analytics integrated into these systems provide insights into production trends and areas needing improvement. Armed with this information, companies can refine their processes further, paving the way for continuous waste reduction strategies.

Embracing smart packaging technology opens doors to both environmental responsibility and cost savings—an ideal scenario for any business looking to enhance its operational efficiency while caring for the planet.

The Role of Artificial Intelligence in Smart Packaging Machinery

Artificial Intelligence (AI) is revolutionizing smart packaging machinery. It enhances automation and precision, making processes faster and more accurate.

With AI algorithms, machines can learn from data over time. This means they adapt to varying production demands without human intervention. For manufacturers, this flexibility leads to optimized operations.

Moreover, AI-powered systems can predict maintenance needs before issues arise. By analyzing performance metrics in real-time, these machines minimize downtime and reduce costs associated with unexpected failures.

Quality control also benefits greatly from AI technology. Intelligent vision systems detect defects instantly during the packaging process. This reduces waste by ensuring only perfect products reach consumers.

The use of AI in smart packaging not only streamlines efficiency but also fosters sustainable practices within the industry. As businesses embrace these advancements, they pave the way for a greener future while maintaining high productivity levels.

Future Trends in the Industry and the Potential Impact on Efficiency and Waste Reduction

The landscape of smart packaging machinery is evolving rapidly. Innovations like advanced robotics and IoT technology are set to redefine production lines. This shift promises not just speed, but also adaptability in response to market demands.

Sustainability continues to be a driving force. Companies are prioritizing eco-friendly materials that can seamlessly integrate with smart systems. These advancements help minimize resource usage while maximizing output quality.

Moreover, predictive analytics will play a pivotal role in the future. By analyzing data trends, businesses can refine their processes further, reducing both downtime and waste significantly.

As customization becomes more feasible, manufacturers will likely see an uptick in consumer satisfaction without compromising efficiency. The combination of these trends suggests a promising horizon where productivity meets environmental responsibility effortlessly.

Conclusion: Why Every Business Should Consider Investing in Smart Packaging Machinery

Smart packaging machinery represents a significant leap forward in manufacturing and distribution. By integrating this advanced technology, businesses can streamline their operations while minimizing waste. The benefits are clear: improved efficiency translates to faster production times and lower operational costs.

Companies that adopt smart packaging solutions often find themselves with a competitive edge. They not only meet consumer demands for sustainability but also enhance their brand reputation through responsible practices.

Investing in smart packaging machinery is not just about keeping up with industry trends; it’s about future-proofing your business. As the market evolves, companies that prioritize efficiency and waste reduction will be better positioned for long-term success.

For any business looking to thrive in today’s fast-paced environment, embracing smart packaging technology is an essential step toward achieving both operational excellence and environmental responsibility.