Introduction to Automation in the Packaging Industry

The packaging industry is undergoing a revolution. As technology advances at breakneck speed, the integration of automation is becoming essential for companies looking to stay competitive. Gone are the days when manual processes dominated production lines. Today, Artificial Intelligence (AI) and the Internet of Things (IoT) are leading this transformation, reshaping how businesses approach packaging.

Imagine smart machines that can analyze data in real-time to optimize workflows or sensors that monitor product quality without human intervention. This isn’t just wishful thinking; it’s already happening across various sectors. The potential for increased efficiency, reduced waste, and improved safety makes automation an enticing prospect for manufacturers everywhere.

As we delve deeper into this topic, we’ll explore how AI and IoT are not only enhancing productivity but also paving the way for innovation within the packaging landscape. Join us on this journey through a world where technology meets creativity in packaging like never before!

The Role of Artificial Intelligence (AI) and Internet of Things (IoT) in Packaging Automation

Artificial Intelligence and the Internet of Things are revolutionizing packaging automation. These technologies work hand in hand to streamline operations and enhance efficiency.

AI algorithms analyze vast amounts of data from production lines. This analysis helps identify patterns, predict equipment failures, and optimize workflows. As a result, manufacturers can reduce downtime and improve output quality.

Meanwhile, IoT devices collect real-time data from machines throughout the packaging process. Sensors monitor everything from temperature to humidity levels. This information enables companies to make informed decisions quickly.

Together, AI and IoT facilitate smarter supply chain management. They allow businesses to track inventory levels accurately and automate restocking processes seamlessly.

The integration of these technologies transforms traditional practices into agile systems that respond rapidly to market demands while minimizing costs.

Benefits of Automation in the Packaging Industry

Automation transforms the packaging industry, offering numerous advantages that enhance productivity. With machines taking over repetitive tasks, companies can significantly reduce labor costs. This shift allows human workers to focus on more strategic roles.

Consistency is another key benefit. Automated systems ensure uniformity in packaging quality and design, reducing errors and waste. This reliability builds trust with consumers who expect high standards.

Moreover, automation speeds up production processes. Products move swiftly through each stage of development, leading to faster time-to-market for new items.

Data collection becomes seamless as well. Integrated systems provide real-time insights into operations, helping businesses make informed decisions quickly.

Sustainability efforts gain traction through automation. Efficient use of materials minimizes waste while optimizing resource consumption—an essential aspect in today’s eco-conscious market.

Current Applications of AI and IoT in Packaging

The integration of AI and IoT in packaging is transforming operations across various sectors. Smart sensors play a pivotal role, monitoring products throughout their journey—ensuring optimal conditions for sensitive items like pharmaceuticals and perishable goods.

Robotics, powered by AI algorithms, streamline packing processes. These machines can adapt to different product shapes and sizes without extensive reprogramming.

Data analytics also comes into play. By analyzing real-time data from IoT devices, companies gain insights into consumer behavior and track inventory trends effortlessly.

Predictive maintenance improves machinery uptime. Sensors detect anomalies before they lead to breakdowns, saving both time and resources.

Moreover, automated quality control systems leverage AI to identify defects faster than human inspectors could ever achieve. This leads to fewer returns and enhanced customer satisfaction while reducing waste in the supply chain.

Case Studies: Successful Implementation of Automation in Packaging Companies

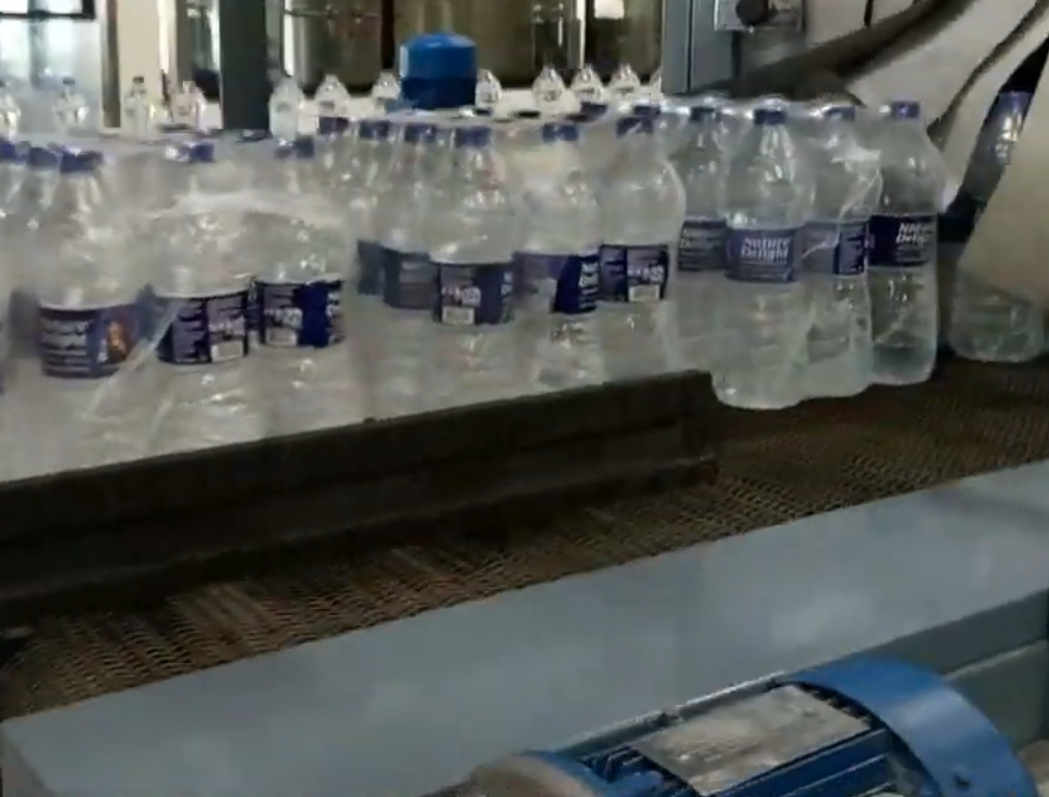

Several companies are leading the way in automation within the packaging sector. One notable case is a beverage manufacturer that integrated AI-driven robots on its production line. These machines improved efficiency by reducing labor costs and increasing output speed.

Another example features a cosmetics company utilizing IoT sensors for real-time monitoring of their packaging processes. This system allowed them to pinpoint bottlenecks quickly, minimizing downtime and ensuring consistent quality control.

A food producer adopted machine learning algorithms to optimize their packaging design based on consumer preferences. By analyzing purchasing data, they tailored packages that enhanced shelf appeal while lowering material waste.

These examples illustrate how various players in the industry are harnessing technology to streamline operations, cut costs, and boost productivity. The success stories highlight an ongoing shift towards smarter solutions in packaging automation.

Challenges and Concerns Regarding Automation in the Packaging Industry

The rise of automation in the packaging industry brings with it a set of challenges. One significant concern is job displacement. As machines become more efficient, many fear that skilled labor will be rendered obsolete.

Another challenge involves the initial investment costs. Upgrading to automated systems can require substantial financial resources, which may not be feasible for smaller companies.

Data security also poses a risk as IoT devices become commonplace. With increased connectivity comes vulnerability to cyberattacks, putting sensitive information at stake.

Additionally, reliance on technology can lead to operational hiccups if systems malfunction or face downtime. Such disruptions might affect production schedules and supply chain integrity.

There’s an ongoing debate about quality control. While automation enhances efficiency, ensuring consistent product quality remains crucial and complex amidst rapid technological advancements.

Future Predictions for Automation in Packaging

The future of automation in the packaging industry is poised for remarkable advancements. As technology evolves, we can expect AI and IoT to become even more integrated into production lines.

Smart factories will dominate, with machines communicating seamlessly. This interconnectivity will lead to real-time data analysis, enabling swift adjustments and enhanced efficiency.

We might also see a shift towards sustainable practices driven by automated solutions. Packaging waste could be reduced through intelligent systems that optimize material usage without sacrificing quality.

Additionally, personalized packaging may rise as consumers demand tailored experiences. Automation technologies will allow manufacturers to adapt quickly to changing preferences while maintaining high output rates.

As machine learning continues to grow, predictive maintenance could minimize downtime significantly. Businesses may rely less on human intervention for routine tasks, allowing employees to focus on innovation rather than repetitive work.

These trends promise an exciting landscape where automation redefines productivity and sustainability in packaging.

Conclusion

The packaging industry is undergoing a transformative phase, driven by automation enhanced through artificial intelligence and the Internet of Things. As companies embrace these technologies, they are not only streamlining their processes but also improving efficiency and product quality. The benefits are clear: reduced costs, faster production times, and increased flexibility.

Current applications demonstrate the versatility of AI and IoT in various stages of packaging—from design to distribution. Case studies reveal that organizations implementing these solutions have seen tangible results, reinforcing the positive impact on operational performance.

However, challenges remain. Concerns around job displacement and data security pose significant questions that need addressing as we move forward. Balancing innovation with ethical considerations will be crucial for sustainable growth in this sector.

Looking ahead, predictions suggest an even deeper integration of automation within packaging operations. With continuous advancements in technology paired with increasing consumer demands for efficiency and sustainability, the future appears bright for those willing to adapt.

Automation in the Packaging Industry is more than just a trend; it’s a pivotal shift that promises to redefine how products are packaged globally.