The Empty Container Air Conveyor System (ECACS) is a revolutionary new way to move, store and manage empty containers in the supply chain. It is a fully automated system that allows for the efficient transportation of empty containers through an air-conveyor belt system. The system eliminates manual handling of the containers, making it more efficient and cost-effective. Additionally, ECACS systems are designed to be highly modular and scalable, allowing them to be tailored to fit nearly any application. In this blog post, we will explore how ECACS systems work, as well as their many advantages and potential applications in the supply chain.

What is an Empty Container Air Conveyor System?

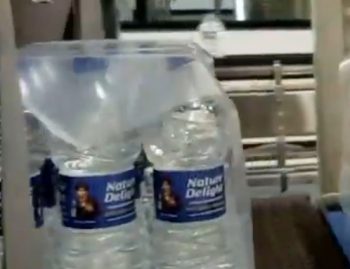

An empty container air conveyor system is a system used to move empty containers from one location to another. The system consists of a conveyor belt that moves the containers through the air, and a series of pulleys and rollers that keep the containers moving along the belt. The system can be used to move containers from one room to another, or from one building to another.

How Does an Empty Container Air Conveyor System Work?

An empty container air conveyor system is a material handling system that uses pressurized air to move containers along a set path. The system consists of an air compressor, an air supply line, and a series of pneumatically-actuated components that move the containers.

The system is controlled by a central computer that regulates the flow of air and the movement of the containers. The computer is programmed to optimize the conveyor system for speed and efficiency.

The Benefits of an Empty Container Air Conveyor System

An empty container air conveyor system can offer many benefits for facilities that handle large volumes of containers. One advantage is that it can help to reduce the amount of time needed to unload containers from trucks. This can help to improve the efficiency of operations and reduce costs.

Another benefit is that an empty container air conveyor system can help to improve safety in the workplace. This is because it can help to reduce the amount of manual handling of containers, which can reduce the risk of injuries.

Finally, an empty container air conveyor system can also help to improve the environment in the workplace. This is because it can help to reduce the amount of dust and other airborne contaminants that are generated when containers are unloaded manually.

How to Choose the Right Empty Container Air Conveyor System for Your Business

When it comes to choosing an air conveyor system for your business, there are a few things you need to take into account. The first is the type of business you have. If you have a small business, then a smaller system may be all you need. But if you have a large business, then you'll need a larger system. The second thing to consider is the amount of space you have available. If you have a lot of space, then you can choose a system that's bigger and has more features. But if you're limited on space, then you'll need to choose a smaller system. And finally, you need to decide what kind of features you want in your system. Do you want something simple or something that's more complex? Once you've decided on these things, then you can start shopping for the right empty container air conveyor system for your business.

Empty Container Air Conveyor System FAQs

1. What is an empty container air conveyor system?

An empty container air conveyor system is a type of material handling equipment that is used to move empty containers from one location to another. The system typically consists of an infeed conveyor, an empty container handler, and an outfeed conveyor.

2. How does an empty container air conveyor system work?

The infeed conveyor is used to bring the empty containers into the system. The handler then picks up the containers and places them onto the outfeed conveyor. The outfeed conveyor then transports the containers to the next destination.

3. What are the benefits of using an empty container air conveyor system?

There are many benefits to using an empty container air conveyor system, including:

- Reduced labor costs: An automated system requires less labor to operate than a manual system.

- Increased productivity: An automated system can handle more containers per hour than a manual system.

-Improved safety: Automated systems minimize the risks associated with manual handling of containers

Conclusion

In conclusion, an empty container air conveyor system is a valuable tool for businesses that need to quickly and safely move containers from one location to another. With its high speed capabilities and low maintenance requirements, it can be used in almost any type of application. Additionally, the system is highly customizable so that each business can tailor it to their specific needs. If you're looking for a reliable way to transport your goods with minimal effort, an empty container air conveyor may be just what you need!